4.

Machining, fixing, jointing, bonding and finishing of the BETONWOOD

building boards

4.1 MACHINING OF BETONWOOD

BUILDING BOARDS

4.11 Basic principles of machining

Machining of BETONYP building board requires the use of carbide tipped

tools. Traditional (iron, chrome-vanadium) hand-held tools can also be

used for machining, however, the tool wear will increase in this case.

The

use of metallurgical tools-metal saws, metal borers-also facilitates

manual processing. It is recommended to provide for dust exhaustion of

appropriate efficiency, when machining BETONYP building boards.

The

min. exhaustion speed should be 30 m/s.

4.12 Recommendations for major operations using hand-held electric and

pneumatic machines

4.121 Cutting-of and cutting to size

It is

recommended to use carbide tipped saws. The cutting depth shall be

adjusted so that the saw blade protrudes only slightly (3-8 mm) from the

BETONYP building board. Favourable edge quality, improved edge

durability and low cutting resistance can be obtained by the use of

carbide tipped saw blades. The “A” and straight tooth types are arranged

alternately. Saw blades with other shape can also be used, the edge

durability edge, however, be reduced.

(nmin

= 4500 min-1 = 75 s-1)

4.122 Groove cutting and mortising

It is

recommended to use carbide tipped ripsaws. (v = 1,5-6 mm).

(nmin

= 5300 min-1 = 88 s-1)

4.123 Circular and other offcuts

Electric compass saw can be used for cutting holes with a diameter

larger than 30 mm as well as for cutting various forms and for angular

cutting.

(nmin

= 1600 strokes/min).

4.124 Boring

High-speed steel or-in series production-carbide tipped borers are

recommended to use for this operation (nmin = 400 W; nmin = 1200 Min-1 =

20 s-1)

The

higher the r.p.m. of the boring machine, the cleaner bores can be

obtained. It is recommended to use hardwood counterpiece on the exit

side of the borer. Feed rate should be maintened at low value.

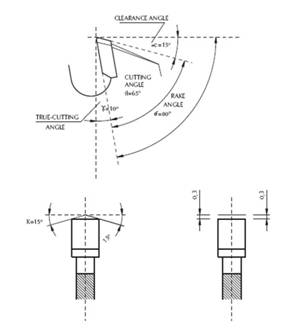

Recommended type of carbide tipped borers:

· From 1,5 to 16 mm diameter: helical drill with 60°C cone angle

· From 8 to 16 mm diameter: mortiser with guide tip and scoring edge

· From 16 to 40 mm diameter: hinge borers with tuide tip and cutting edges

Borers with diameter from 1,5 to 16 mm can be provided with counter

sinking fixtures having carbide tipped cutting edge.

4.125 Milling

It is

recommended to use carbide tipped cutters for this operation , too.

Cutter sets with reversible blades ensure quick tool replacement and

high accuracy.

(nmin

= 22000 min-1 = 367 s-1)

4.126

Sanding

Uneveness in joint can be elimanated by sanding. Recommended grit size

of the sanding paper: 60-80. Appropriate cutting depth can be achieved

only by the use of belt sanders. Dust exhaustion should be provided

under any circumstances.

(v =

350m/min)

(nmin =

4500 min-1 = 75 s-1).

4.127 Nailing, clamping

The

mechanically prebored BETONYP building boards can be nailed using manual

methods. Their fixing to natural wood material can be carried out

efficiently by means of mechanical nailers and pneumatic clampers with

automatic feed. The wood-board joint can be improved significantly by

the use of spiral nail.

4.

128 Screwing

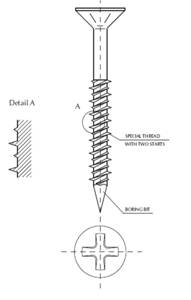

In

series production the BETONYP building boards can be screwed to ribs

using pneumatic or electric screw-driving machines. When assembling

structures, screw with two-start thread can be used most efficiently.

preboring screw

4.2

FIXING OF THE BETONYP BUILDING BOARDS

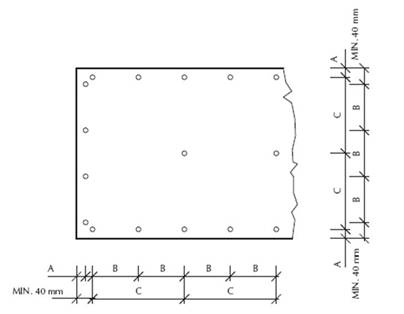

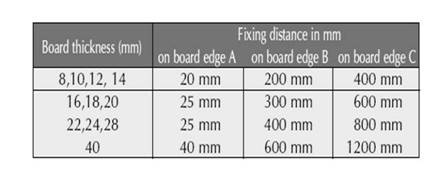

The

cement-bonded chipboards can be fixed by pneumatic and manual nailing,

spiral nailing, screwing and pneumatic clamping.

When

fixing the cement-bonded chipboards, they have to be placed on the frame

ribs accurately.

- The

fixing distances at corners are to be selected so that excessive

weakening of cross-section may not occur.

- It

is recommended to apply screwen fixing for boards with more than 16

mm thickness.

- It

is required to use plated/corrosion resistant/fasteners and

fittings/zinc-plated, cadmiated etc./

- Proper support of boards should be provided during fixing for any

assembly method.

4.3

FORMING OF JOINTS

When

designing BETONYP structures, the following recommendations should be

considered in connection with making extension:

- Dimensional change of the building component depending on

temperature

- Dimensional changes depending on moisture content

- Movement of load bearing structure

- External effects, loads (wind pressure, vibration, etc.)

- Fasteners (type, size, quantity etc.)

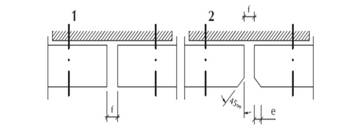

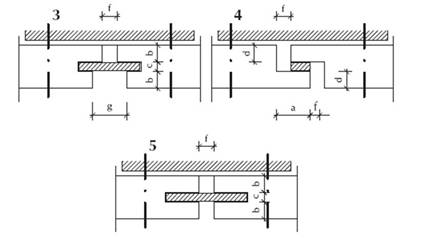

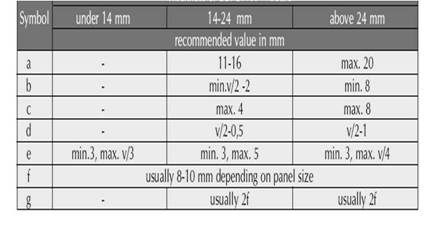

4.31

Visible joints

A

wide range of extensions can be made with BETONYP boards by various edge

forming.

4.4

BONDING

Before the selection and the application of an adhesive for BETONYP

boards it is highly recommended to ask for technical information at the

supplier of the adhesive.

4.5 FINISHING, PAINTING

When finishing BETONYP building boards, the following properties of

board should be considered:

- Due

to its considerable cement content, the board shows alkaline

reaction (similarly to concrete)

- The

boards surface is smooth and quite high absorbent

- The

moisture content of board should not exceed 14%.

Due to

the alkaline of board, either alkaline resistant materials should be

used for finishing BETONWOOD boards or alkaline resistant prime coat

should be applied to the boards.

Purpose of priming:

- To

reduce surface alkalinity

- To

make absorbance uniform

- To

decrease moisture adsorption

The so

called “deep primers” resistant to alkalis (that do not show

saponification on the surface) can be used for this purpose.

Before the application of the finishing materials it is highly

recommended to ask for technical information at their suppliers.

Repair of minor damages of the board:

Deep

prime the damaged part together with the other parts of the surface,

then fill the gap using DEKO putty. Once dried, align the puttied part

with the sound parts of the surface by sanding.

To

paint BETONYP building boards it is recommended to use complete coating

systems developed by various paint manufacturing companies.

4.6 WALL-PAPERING

Wall-papering is a generally recommended surface finishing method for

living rooms.

Surface

preparation: Finishing of joint gaps or

repair of possible surface defects by gypsum plastering (Breplasta). To

compensate for the possible slight movement of structure, elastic

polystyrene foam board or gypsum plasterboard is placed under the

wall-paper. This sliding layer gives a surface ready for final surface

forming.

- Wall

papering with polystyrene underlay: The wallpaper underlay is

available in panel sizes. Make sure that the vertical strips are

jointles. The edge-to-edge joint should not coincide with the panel

joint and should preferably be free of gap.

First

apply adhesive uniformly to the wall surface to be papered (by means of

brush and distributing comb), then to the wall-paper underlay. Surfaces

prepared this way should be left drying for about 10 min. A 3-4 m2 area of wall surface is recommended to be papered simultaneously.

The wall-paper underlay can be applied to the wall

surface by means of TEDDY roller so that the air enclosed between

layers is squeezed out, when moving the roller in one direction.

- Wall-papering with gypsum plasterboard: The gypsum plasterboard is

available in panel form, which should be cut to size accurately

prior to placing. The panel is to be fixed by screwing, starting at

the centre and proceeding downwards. The panel should be fixed on

its periphery and centre line alike to the panel ribs, making sure

that the juncture of panel joint and gypsum plasterboard is in ofset

position. Full threaded chipboard screw of min. 35 mm lenght is to

be used. The fixing distance is max. 200 mm and min. 15 mm from the

board edge. The gap formed between screwed-on panels should be

filled with gap-filling gypsum. The location of screw-heads is to be

masked by gypsum plastering.

The

wall-papering technology used for surfaces prepared this way is similar

to that applied for traditional wall surfaces.

For light wall-papers with overlapped joint, the

wall-paper can be applied directly to the foam board without surface

justifying. Special wall-papers and claddings can be bonded with

water-based dispersion adhesive. Particular care should be taken, when

wall-papering vertical wall corners. Do not take over the wall-papers

continuously to the neighbouring wall surfaces. Here the wall-papers

should be jointed by leaving slight overlaps and bonding only one of the

overlapping layers.

It is recommended to perform wall-papering prior to

locating the cover fillets and skirting boards, because it facilitates

jointing of wall-paper borders at the horizontal edges and at the

skirtings of doors and windows.

Important: The adhesive, putty, paint used for PS foam board may not contain

organic solvent.

4.7 CLADDINGS FOR

“ROOMS EXPOSED TO WET CONDITIONS”

4.7.1 PVC cladding systems

The cladding systems are suitable for making

jointless, high resilint claddings in “rooms exposed to wet

conditions”/toilet, bathroom, lavatory/ and on wall surfaces above

kitchen worktop.

The

uneveness of socle and floor slab under the flooring board should be

eliminated. The following socle finishing materials can be used for

ground-floor rooms: polymer mortar, self-spreading floor mass.

- The

surface defects in panels under the wall-cladding material can be

repaired with DEKO putty.

- First the floor covering should be prepared. The flooring material

laid free of gap should be welded together at the joints.

Water-tight, trough-like layer should be formed by felding the floor

covering to the vertical wall surfaces in min. 10 cm height. Special

care should be taken, when welding the corners.

- The

wall cladding should be bonded free of gap by cutting it so that the

wall cladding material 5 cm overlaps the folded edges of the floor

covering formed in a trough-like fashion. Thus it can be ensured

that no utility water enters the panel structure of the building.

Bonding of PVC coverings is recommended to be performed by

specialist.

4.72

Tiling

Tiles form a stiff layer on the

wall surface (or on the floor), therefore, the following instructions

should be observed, when covering with tiles:

It is

recommended to design an extraordinary solid load-bearing structure

(solid frame building, regular fixing of boards). The movement of

load-bearing structure might cause splitting or even breaking of tiles.

The tiles should be applied in a netted structure, leaving min. 3 mm gap

between tiles. Similarly, when forming corners, min. 3 mm gap is

required.

At corners joints, only permanently elastic material is permitted to be

used for filling the gaps (Silicon or Acrylpaste). It is important to

take into consideration that silicon type filling materials can not be

coloured or painted afterwards. Therefore using silicon filling

material, coloured type should be applied. Acryl pastes can be

painted afterwards.

Specially at bigger wall facing an elastic material has to be placed

between the BETONYP boards and tiles in order that to form a sliding

layer. This layer can be a polystyrene foam board to instructions (PS

board by bonding, gypsum board by screwing).

Tiling can be made on this surfaces. When bonding the tiles on, the

adhesive supplier’s instructions must be followed.

If the flooring of the room exposed to wet conditions in the roof space

is also made of ceramics – especially if BETONYP floor is placed between

the ground-floor and the loft - , reliable water proofing should be

provided.

This insulation can be

renderset (BITUGEL) and bonded (bitumen + bituminous boards).

The insulation should be made by

folding it to the side walls by min. 10 cm.

BITUGEL should be used to bond

the ceramic covering to the insulation prepared this way.

At the corners elastic material

should be used for filling the gaps.

5. Basic principles of the

BETONYP structures

The

previous chapters gave an introduction to the application, the physical

properties, and the main features of the BETONYP building boards.

Obviously the BETONYP building boards can be used in several area of the

building industry.

BETONWOOD. and its predecessors

also used to produce plane boards, differently processed board products,

and to manufacture and distribute products, constructions and elements

for so called complete loading systems. For now this later activity has

been ceased on the one hand because of an intention for clearing the

company’s profile and on the other hand because of the complicated

constructions of boarding systems and the complexity of customer

response and serving the client’s demands on a standard of our days.

Our intention was that the

development, design, manufacturing, and distribution of constructions

can be formed by using BETONYP building boards are to be accomplished by

professional contractors specialised on this kind of activities

providing our customers with the highest competence and expertise.

In spite of these events, during

those years which were dedicated to introduce the BETONYP building

boards into the market and to get them accepted by both the domestic and

foreign customers in building industry, BETONWOOD and its

predecessors have gained significant experience and expertise in

connection with the application of the building boards. Therefore now we

can publish some basic feature and possible purposes for the application

of the product in order that our clients can derive benefit from them

during the application of our board products.

Important!

It is essential that BETONYP building board is a basic commodity

produced for the building industry similarly to the brick or cement.

Therefore it is very important to accentuate again that any product or

construction applying BETONYP building boards has to be designed taking

customer requirements into account previously.

During

the design process the physical, mechanical, fire resistance and

airborne sound insulation properties of building boards must be taken

into consideration.

|